Advanced

At the Advanced accuracy level, our focus is on the perfect interaction between human, machine and environment for maximum accuracy and precision which almost no other measurement service provider can offer. Our areas of application are the high-precision industry and 3D calibrations.

Intermediate

The Intermediate accuracy level focuses on a high level of accuracy, precision and efficiency and is perfectly suited for the precision industry, from individual parts to large-scale production as well as 3D calibrations.

Basic

The Basic accuracy level combines high performance with maximum cost efficiency, and is precise and safe. This makes it perfectly suited for all standard measurement tasks, individual parts as well as large-scale production.

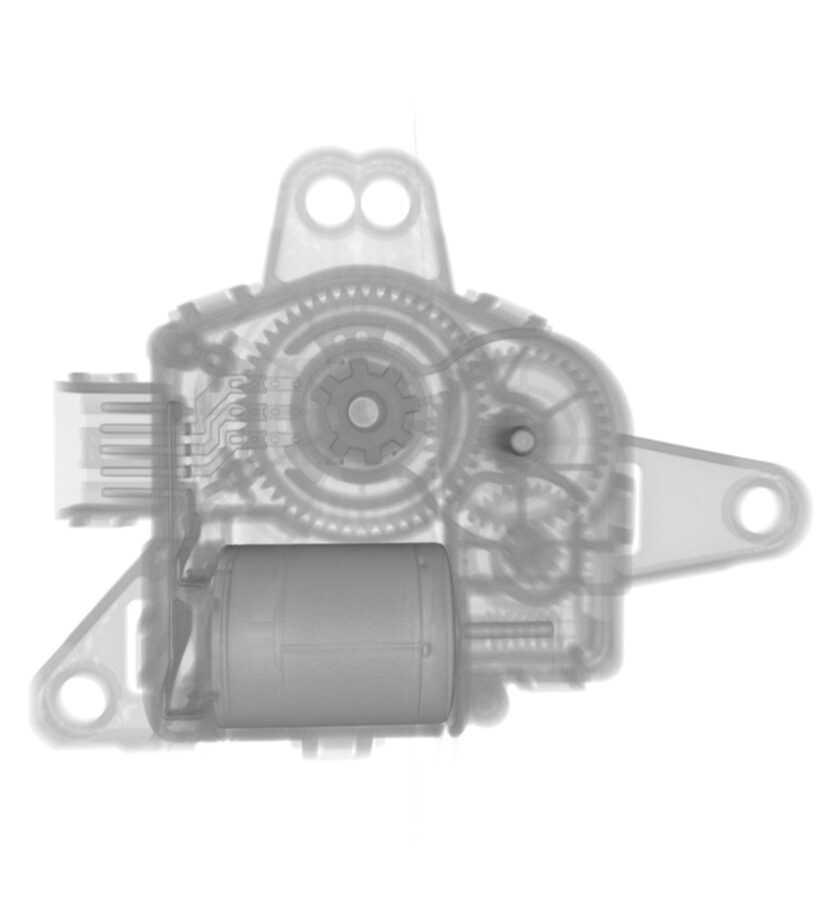

CT accuracy

Complete component measurement and fast scans are the key to efficient component analysis. The accuracy depends on the material density, the quality of the parts, wall thicknesses, etc.